RFID Inventory Systems

RFID systems that enable efficient and accurate inventory management in warehouse and intralogistics

When it comes to warehouse and production environments, RFID systems help automate workflows, procedures, and data collection.

The technology provides an effective solution to manage the inventory flow and information across the warehouse, production, and shipment, for better inventory management and purchasing decisions.

Supply chains span the globe, multiplying the number of stakeholders and adding to the overall complexity of inventory management. Production, on the other hand, relies on complex procedures and systems (WMS, ERP, Supply Chain Management, etc.).

RFID makes a difference by functioning at high speeds and capacities while allowing for automated tracking, identification, and tracing down to item-level.

Automated warehouse solutions help automate every step of inventory management from acceptance through to storage location and issuance.

Reception – Warehouse RFID solutions accelerate the reception of components and materials and their registration into inventory. All incoming goods can be RFID labeled at reception or provided with RFID identification by the supplier.

Real-time visibility – RFID tags for inventory are implemented for each individual item or at the container level, using the organization’s identification system and materials typology. The same systems also help accelerate the issuance and transfer of materials, while providing accurate availability in real-time.

Inventory control – Warehouse management involves annual and regular inventory audits that are labor-intensive. RFID helps greatly simplify the counting procedures, ensuring inventory data in the WMS/ERP always matches the real warehouse situation 100%.

RFID offers powerful solutions to tackle common reusable transport packaging management issues such as inventory shrinkage and asset utilization.

Returnable packaging and carriers are essential in intralogistics with various types of containers are used to transfer materials and goods. By incorporating RFID into their workflow, organizations can account for the real-time status of their condition and location.

Durable RFID tags enable the retrofitting and the source-tagging of any type of packaging such as pallets, bins, totes, crates, trays, product hangers, paint shop skids, food containers, and beer kegs.

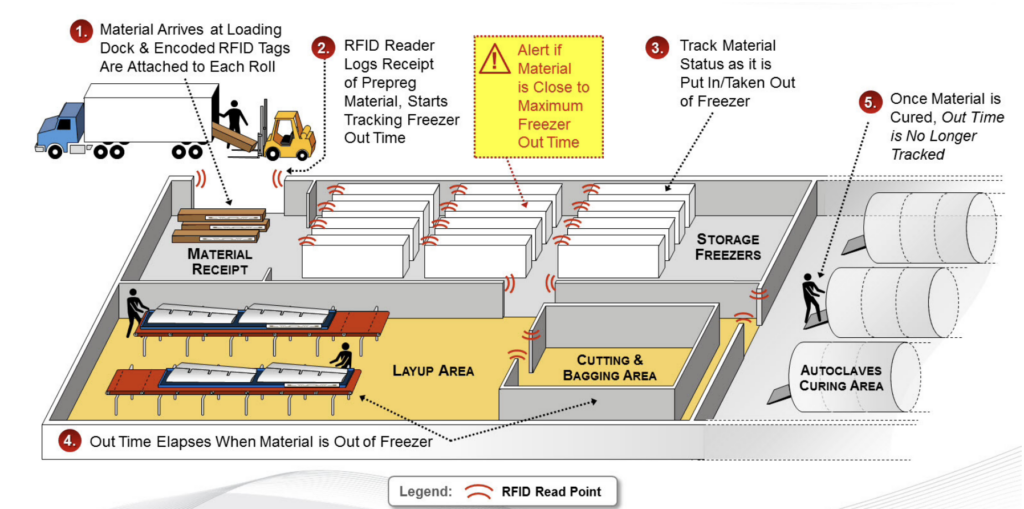

RFID systems enable paperless materials management in complex manufacturing, providing inventory visibility and flexibility.

Lean manufacturing operations rely on high-performing supply chains for just-in-time supplies.

Paper and barcodes labels only offer basic tracking and automation features. RFID technology on the other hand enables seamless tracking of any type of materials, parts, components.

Production logistics RFID systems help reduce quality errors and enable full traceability by leveraging the data captured to provide real-time visibility into material consumption, record production batches, and monitor production parameters.

Work-in-Process (WIP) inventory management is essential for achieving a lean manufacturing organization.

RFID inventory management systems for WIP give real-time information to production control systems, allowing them to monitor and notify on every batch and order in process. The parameters are monitored and recorded to document the manufacturing process for quality and traceability.

Furthermore, RFID technologies help with the identification and correction of process inefficiencies. With accurate location management, operations with multiple and vast storage facilities such as in automotive manufacturing benefit from automated product identification and reduced picking time.

Case Studies RFID Inventory

Impact of RFID Inventory Systems

>99% Inventory Accuracy

Improved item identification and tracking: RFID technology enables swift and automated data capture, reducing manual efforts and errors in inventory tracking.

10x Faster Inventory Audits

Reduce audit cycle times from days to hours.

+30% Inventory Turnover

Reduced carrying costs and improved cash flow: RFID tracking helps optimizing stock levels and replenishment strategies, reducing excess inventory and stockouts.

40-60% Less Manual Labor

Reduce hours spent on data entry and scanning tasks.

30-50% Faster Receiving

Allow for faster verification of incoming shipments and quicker integration into inventory.

FAQs RFID Inventory

Inventory Management at Item-Level with RFID

While barcodes require perfect circumstances to operate, RFID operates in environments deemed too harsh, such as where dirt or wear-and-tear would make line-of-sight elusive.

RFID tags come in various levels of durability and cost-effectiveness. This allows all materials, parts, consumables, containers, and work-in-process inventories to be identified and tracked at either the item or the container level:

Wide range of form factors from RFID labels to rugged tagged, to fit every inventory item in terms of sizes and read ranges.

RF performance can be optimized for any surface, including metal, plastic, and wood.

Adhesives, hang ties, zip ties, magnets, screws, and other mounting options will provide maximum flexibility and durability in any configuration.

Unique serial numbers are a key requirement and can be handled by the manufacturer’s service bureau or encoded using RFID equipment. Likewise, printed RFID labels will greatly simplify deployment and offer hybrid readability when custom printed with texts and barcodes.

Tracking Reusable Transport Packaging with RFID

Bulk bins, containers, and pallets can all be tracked with RFID inventory tags.

Warehouse Automation with RFID Readers

RFID readers are strategically placed at choke points to track the movement of items around the warehouse and production facility:

- On dock doors, gates, and portals to offer the coverage needed for data capture while not hindering workflows.

- On forklifts and vehicles.

- Overhead and mobile readers to add flexibility to the workflow by allowing for on-the-spot checks and data capturing.

Turn-key solutions are also available for particular processes, including acceptance, dispatch, check-in-check-out.

Which Warehouse Management Systems Work With RFID

All leading warehouse management systems are interoperable with RFID.

The inventory management software provides the user interface for monitoring and managing inventory data collected through the RFID system. It processes and presents real-time information about item locations, quantities, movement, and status. Inventory management software may also include features like reporting, analytics, alerts, and integration with other business systems.

As for middleware, it serves as the bridge between RFID hardware and software applications. It manages tag data, filters and processes it, and then sends relevant information to the inventory management software. Middleware ensures smooth integration between the physical RFID and digital software layers.

Improving Inventory Accuracy

Data accuracy is achieved by designing read zones with precise positioning and calibration for data gathering over long and/or short distances and at high speed while preventing stray reads.

The whole organization will depend on the data generated to effectively: Control the flow of goods, Adjust stocks in the ERP, Trigger new orders, Locate where the goods are and where are they going, Optimize overall business processes.