RFID For Oil and Gas

Asset Tracking

RFID technology to drive safety, reduce non-productive downtime, enhance operational efficiencies, and extend Oil and Gas asset lifecycles

Managing critical assets like drill pipes, valves, and tubulars under extreme conditions presents significant challenges for oilfield services companies. RFID technology offers real-time tracking, lifecycle monitoring, and inspection automation to enhance operational efficiency, improve safety, and ensure regulatory compliance, even in the harshest environments.

Xerafy has been at the forefront of transforming RFID technology from a supply chain management tool to an essential tracking solution for oilfield services companies. Our rugged RFID tagging solutions, co-developed with industry leaders, are engineered to withstand extreme pressures, deepwater conditions, and exposure to chemicals, addressing key challenges such as equipment maintenance, asset visibility, and compliance across drilling, fracking, and offshore operations.

From tracking drill pipes and tubulars to monitoring critical rigging and lifting assets, Xerafy’s RFID technology provides a scalable, reliable solution for operational efficiency. Our case studies demonstrate how leading oil and gas companies are leveraging RFID to reduce downtime, improve maintenance, and enhance safety. Beyond oil and gas, Xerafy’s RFID solutions are equally adaptable to the demanding environments of Mining and Construction, offering robust asset management across multiple industries.

Drill pipes are critical, high-value assets in oilfield drilling operations, forming the majority of a drill string’s length. Managing these assets effectively throughout their lifecycle is essential to ensure safety, reduce downtime, and optimize maintenance costs.

Traditional manual tracking methods lead to unreliable data, overlooked inspections, and excessive wear, all of which risk costly failures and downtime:

Manual tracking results in inaccurate pipe lifecycle data and missed inspections.

Inspections often rely on external signs of wear rather than precise operational metrics.

Pipe failures and fatigue damage lead to non-productive time (NPT) and increased risks.

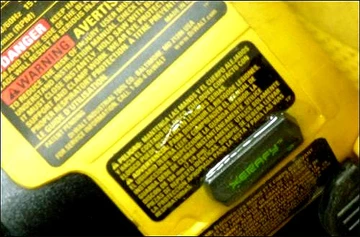

Xerafy’s ultra-rugged UHF RFID tags are flush-mounted into drill pipe joints, creating a unique digital identity for each section. The RFID tags are readable even in HPHT (High-Pressure High-Temperature) drilling environments, enabling automated tracking throughout operations:

Automated Pipe Tallying: Fixed RFID readers, situated below the rotor, identify individual pipes as they are tripped in and out of the well, automating pipe tally counts.

Inventory and Yard Management: Real-time tracking streamlines pipe storage, handling, and inspections, ensuring accurate location and availability.

Lifecycle Data Management: Location, operating time, circulation hours, fatigue accumulation, and inspection results are recorded and updated for each pipe.

Fatigue and Wear Monitoring: Identify pipes nearing their fatigue limits to proactively schedule inspections and maintenance.

Repairs and Maintenance: RFID data enables targeted, efficient repairs, reducing costs and extending pipe lifecycles.

Xerafy’s patent-pending antenna design allows RFID tags to be embedded securely in drill pipe joints, transforming the asset’s metal into part of the RF antenna for enhanced readability. The system ensures real-time data accuracy and traceability across the entire lifecycle of the drill pipe.

By streamlining handling procedures and automating identification, RFID significantly improves operational efficiency and safety:

Improved Lifecycle Management: Individual tracking improves accuracy for inspections, repairs, and replacements.

Reduced Downtime: Proactive maintenance reduces the risk of failures, cutting non-productive time.

Cost Optimization: Extended pipe lifecycles and fewer unplanned replacements deliver measurable cost savings.

Enhanced Safety: Accurate monitoring reduces safety risks associated with pipe failures.

Downhole tools and drill bits operate under extreme conditions, including high pressure, high temperatures (HPHT), abrasive materials, and exposure to harsh chemicals.

Traditional tracking methods often fail to provide accurate, real-time data, making lifecycle management and maintenance challenging:

Limited tracking visibility for individual downhole tools and drill bits.

High failure rates due to wear, fatigue, and external damage under extreme conditions.

Manual identification methods are prone to errors and inefficiencies.

Limited space and design constraints restrict the mounting of conventional tags.

Xerafy’s rugged embedded RFID tagging solutions are engineered to track downhole tools and drill bits with precision and reliability. RFID tags can be securely embedded into the small form factors of these tools while maintaining durability and performance:

Tool Lifecycle Management: Track operating hours, usage cycles, and location data for each tool.

Wear and Tear Monitoring: Monitor fatigue accumulation and abrasion to identify tools requiring maintenance or replacement.

Real-Time Visibility: Fixed and handheld readers enable accurate, automated data capture even in HPHT environments.

Compact, Durable Tags: Xerafy’s specialized antenna design allows RFID tags to be embedded into limited mounting areas, withstanding vibrations, fluids, and extreme pressures.

Automated Inspections and Workflows: RFID automates inspection processes by providing real-time data for tool condition, usage cycles, and required maintenance, reducing manual errors and improving efficiency.

Tracking Additional Downhole Tools: Xerafy’s solutions extend to a range of downhole tools beyond drill bits, including logging tools, stabilizers, and drilling motors.

Xerafy’s RFID tagging solutions provide operators with accurate, actionable data for managing downhole tools and drill bits, improving reliability, reducing costs, and optimizing performance in extreme oilfield environments. By automating inspections and enhancing lifecycle tracking, Xerafy enables oilfield operators to maintain peak performance across their entire drilling and downhole equipment:

Extended Tool Lifespan: Proactive tracking and maintenance extend the operational life of downhole tools and drill bits.

Reduced Downtime: Real-time monitoring prevents unexpected failures, minimizing costly operational interruptions.

Improved Operational Efficiency: Automated identification eliminates manual processes, reducing errors and inspection time.

Cost Savings: Enhanced visibility enables better asset utilization and reduced replacement costs.

Oilfield casing and tubing, collectively known as OCTG (Oil Country Tubular Goods), play a critical role in well construction and integrity. These tubular assets protect wellbores, support drilling operations, and enable production flow.

Managing their traceability, grading, and lifecycle is essential to ensure safe and cost-effective operations:

Manual tracking of casing and tubing results in inventory inaccuracies and operational delays.

Ensuring proper grading, traceability, and lifecycle data is challenging without automation.

Regulatory compliance for inspections, testing, and certification management is difficult to maintain manually.

Damaged or worn tubulars can compromise well integrity and increase safety risks.

Xerafy’s rugged RFID tagging solutions enable automated tracking and lifecycle management for casing and tubing, ensuring accuracy, efficiency, and safety:

Traceability and Grading Management: RFID tags provide a unique digital identity for each tubular section, enabling traceability from manufacturing to deployment.

Inventory and Yard Management: RFID systems streamline storage, transportation, and yard management, ensuring real-time visibility into OCTG assets.

Lifecycle Monitoring: Track usage cycles, operational hours, and wear data to identify damaged or fatigued tubulars before they compromise well integrity.

Automated Inspection and Maintenance: RFID automates pressure testing, inspection histories, and certification tracking, ensuring compliance with safety standards.

Durability in Harsh Environments: Xerafy’s rugged RFID tags withstand high pressures, extreme temperatures, and corrosive drilling fluids, ensuring long-term performance.

Xerafy’s RFID tagging solutions provide oilfield operators with the tools to ensure accurate traceability, lifecycle monitoring, and compliance for OCTG assets. By automating yard management, inspections, and certifications, RFID enables safer, more efficient, and cost-effective operations for well construction and production:

Improved Well Integrity: Accurate traceability and lifecycle management reduce the risks of failures and well downtime.

Enhanced Operational Efficiency: Automate inventory tracking, inspections, and yard management to streamline workflows and reduce errors.

Regulatory Compliance: Ensure OCTG assets meet grading, testing, and certification standards.

Reduced Downtime: Identify fatigued tubulars and replace them proactively, minimizing operational disruptions.

Cost Savings: Optimize asset utilization, extend lifecycles, and reduce unnecessary replacements.

Rigging and lifting equipment are vital for oilfield operations, where heavy loads are moved under strict safety and compliance requirements.

Traditional tracking and inspection methods, such as paper-based records or QR barcodes, are error-prone and inefficient, increasing operational risks and non-compliance:

Manual identification and inspections are time-consuming and prone to errors.

Tracking equipment lifecycle and compliance certification is difficult to manage.

Equipment is subject to wear and damage from impacts, degreasing, hot washing, and other extreme conditions.

Non-compliance increases safety risks and operational delays.

Xerafy’s rugged RFID tagging solutions provide reliable tracking, compliance verification, and lifecycle management for rigging and lifting equipment:

Durable RFID Tags: Embedded or attached RFID chips withstand impacts, degreasing, hot washing, shot blasting, and painting.

Automated Inspections: RFID eliminates manual data entry by enabling automated identification and real-time retrieval of inspection histories.

Compliance Management: Tags link each asset to its unique digital record, ensuring accurate tracking of certifications, maintenance, and non-compliance status.

Lifecycle Monitoring: Track usage cycles, wear levels, and maintenance schedules to ensure equipment safety and longevity.

Streamlined Workflows: Handheld readers allow operators to efficiently check inventory, trigger replenishments, and update inspection logs in the field.

Xerafy’s RFID tagging solutions provide oilfield operators with accurate, real-time visibility into the condition and compliance of rigging and lifting equipment. By automating workflows and ensuring equipment safety, Xerafy helps improve efficiency, reduce risks, and optimize operational performance:

Improved Safety and Compliance: Automate tracking of certifications and inspections to reduce risks and avoid regulatory penalties.

Increased Operational Efficiency: Eliminate manual record-keeping and streamline maintenance workflows.

Durability in Harsh Environments: RFID tags endure extreme conditions for reliable long-term performance.

Optimized Lifecycle Management: Track wear and tear to maximize the lifespan of rigging and lifting equipment.

Pipeline sections and valves are critical assets for oil and gas midstream operations. Ensuring their reliability and performance requires accurate tracking, maintenance scheduling, and compliance management, especially under extreme operating conditions.

Challenges:

Manual tracking methods are prone to errors and inefficiencies.

Maintenance schedules are difficult to manage without real-time asset data.

Pipeline integrity monitoring and valve inspections require precise location and condition data.

Unplanned failures can result in safety risks, costly repairs, and production downtime.

Xerafy’s rugged RFID tagging solutions enable real-time tracking and lifecycle management of pipeline sections and valves:

Accurate Asset Identification: RFID tags provide a unique digital identity for each pipeline section or valve, ensuring precise asset traceability.

Real-Time Monitoring: Tags track location, installation history, usage, and pressure levels to streamline inspections and performance analysis.

Condition-Based Maintenance: RFID-enabled systems monitor performance trends and identify assets requiring repair or replacement, enabling predictive maintenance.

Compliance and Integrity Management: Automate reporting and ensure compliance with industry standards by linking tags to inspection records and certifications.

Rugged Durability: RFID tags withstand extreme conditions, including high pressures, corrosive environments, and temperature fluctuations, with ATEX and IECEx certifications for hazardous locations.

Integration with ERP Systems: RFID systems seamlessly integrate with existing ERP and asset management platforms, automating workflows and compliance reporting.

Xerafy’s RFID tagging solutions provide operators with accurate, real-time visibility into pipeline sections and valves, enhancing reliability, safety, and operational efficiency. By automating lifecycle management, condition-based maintenance, and compliance reporting, RFID ensures critical infrastructure operates at peak performance while reducing costs and risks:

Improved Pipeline Integrity: Real-time data ensures proactive maintenance, preventing costly failures and improving reliability.

Reduced Operational Downtime: Streamlined inspections and condition-based maintenance minimize unplanned disruptions.

Enhanced Traceability and Compliance: Automate regulatory reporting and ensure assets meet safety and performance standards.

Optimized Lifecycle Management: Accurate lifecycle tracking reduces repair costs and extends asset lifespans.

Increased Safety: Predictive maintenance helps prevent leaks, ruptures, and environmental hazards, enhancing infrastructure safety.

LPG cylinders are widely used in industrial, commercial, and residential applications, requiring reliable tracking for safety, compliance, and operational efficiency.

Challenges:

Traditional tracking methods for LPG cylinders are prone to errors and inefficiencies.

Mismanagement of cylinder inventory leads to loss, theft, or misuse.

Regulatory compliance for inspections, pressure testing, and maintenance is difficult to manage manually.

Cylinder tracking at filling stations and distribution points lacks real-time accuracy.

Xerafy’s gas cylinders RFID tagging solutions provide end-to-end lifecycle management of LPG cylinders:

Real-Time Inventory Management: RFID tracks cylinder locations across filling stations, distribution points, and end-users.

Automated Inspections: RFID enables seamless pressure testing, maintenance tracking, and compliance reporting.

Loss and Theft Prevention: RFID tags provide accurate identification, reducing the risk of lost or unaccounted cylinders.

Enhanced Consumer Experience: NFC-enabled RFID tags allow consumers to access cylinder details, such as refill status and safety instructions, via mobile devices.

Durable Tags: Xerafy’s RFID tags withstand impacts, pressure changes, and harsh environmental conditions.

Xerafy’s RFID tagging solutions provide gas distributors with accurate, real-time visibility into cylinder inventory and lifecycle status. By automating workflows and ensuring compliance, RFID enables cost savings, operational efficiency, and improved safety across the supply chain:

Improved Operational Efficiency: Automate inventory management, inspections, and maintenance workflows.

Enhanced Compliance: Ensure regulatory requirements for safety inspections and pressure testing are met.

Reduced Loss and Misuse: Accurate tracking minimizes the risk of theft and unaccounted cylinders.

Better Customer Service: Enhance user experience through transparent tracking and refill status updates.

Increased Cylinder Lifespan: Proactive maintenance and pressure testing extend cylinder life while ensuring safety.

Case Studies RFID Oil & Gas

From drill pipes to OCTG and valves, see how Xerafy’s expertise and field-tested RFID technology are transforming oil and gas asset tracking worldwide

Key Benefits of RFID for Oil and Gas Operations

Improved Safety and Compliance

Automating safety inspections and regulatory reporting ensures compliance with industry standards and reduces risks

Cost Savings and Efficiency

RFID streamlines workflows, reduces manual errors, and extends asset usability, delivering significant operational savings

Optimized Yard and Inventory Management

RFID provides real-time visibility into asset locations, improving inventory accuracy and yard efficiency

Reduced Operational Downtime

Predictive maintenance and automated tracking minimize failures and non-productive time (NPT)

Enhanced Asset Lifecycle Management

RFID enables real-time tracking and proactive maintenance to extend asset lifecycles and reduce unexpected failures

FAQs RFID Oil and Gas

What are the challenges of asset tracking in oilfields?

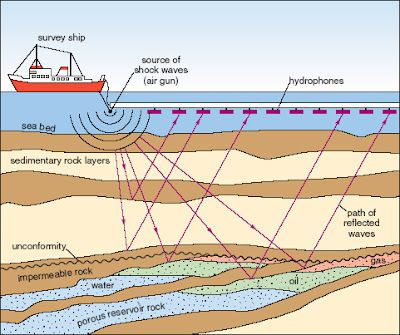

Tracking assets in the oil and gas industry presents unique challenges due to the extreme conditions in drilling, fracking, offshore, and mining operations.

Conventional tracking technologies, such as QR codes and barcodes, struggle in these environments as they require clear visibility and physical integrity. Additionally, remote locations, limited connectivity, and safety hazards complicate data capture and asset management.

Key challenges include:

Durability

Assets are exposed to harsh conditions like high pressure, temperature extremes, and chemical exposure, which can compromise the effectiveness of tracking technologies.

Accessibility

Inspections and maintenance in isolated, high-risk areas are difficult, with limited internet and cellular coverage.

Productivity

Manual tracking is time-consuming, prone to errors, and lacks real-time visibility, leading to delays and unplanned disruptions.

Safety

Ensuring real-time data accuracy without compromising worker safety in hazardous environments is a critical concern.

Can Xerafy RFID tags withstand downhole high-pressure high-temperature environments?

Yes, Xerafy RFID tags are specifically engineered to withstand the extreme conditions commonly found in oilfield environments.

They are designed to endure downhole and high-pressure, high-temperature (HPHT) conditions. Their durable construction also ensures resilience against corrosive chemicals, drilling mud, seawater, and proppant mixes.

Xerafy’s patented antenna design enables these tags to function reliably in metal environments like drill strings and oilfield tools, providing accurate asset tracking even in the most demanding conditions.

How do you secure RFID tags to drill pipes and tubulars?

Securing RFID tags to drill pipes and tubulars can be done using different techniques, depending on the application.

For downhole operations, RFID tags are embedded directly into the tool joints, offering a rugged, flush-mounted solution that ensures durability in extreme conditions. This method allows for real-time tracking of the pipe’s location, movement, wear, and inspection history.

For surface equipment, banding is a common technique. An RFID tag is attached to the pipe or tubular using a secure metal band or strap, making it easier to install and remove as needed.

Both methods allow for accurate asset tracking, enabling efficient maintenance and operational monitoring, whether on the rig floor or in the field.

How do you tag LPG cylinders and tanks with RFID?

Tagging LPG cylinders requires RFID tags that can perform reliably in rugged, real-world conditions—on curved metal surfaces, exposed to pressure-washing, abrasion, and outdoor environments.

The Xylinder OUT is specifically engineered by Xerafy for direct mounting on the steel body of LPG cylinders. It delivers:

+ Strong read range on metal

+ Durable construction for long-term outdoor use

+ Flexible mounting options including riveting, bonding, or adhesive

For other tagging needs—such as the neck, footring, or composite tanks—Xerafy offers a full range of rugged RFID tags designed to adapt to different materials, geometries, and workflows. Each tag is built to withstand the rigors of the LPG supply chain, from filling plants to distribution and customer sites.

Choosing the right tag and installation method is key to successful deployment. Engineers can evaluate real-world performance by testing for:

+ Reader compatibility (RFID handheld reader, gate, tunnel)

+ Mounting suitability (material, curvature, interference)

+ Durability under operational stress (handling, washing, stacking)

What are ATEX-certified RFID readers?

ATEX-certified RFID readers are designed for use in hazardous environments where explosive atmospheres may be present, such as oil and gas fields.

These readers detect RFID tags and automatically transmit data in real-time to a central database, ensuring continuous asset visibility and traceability. The selection of ATEX-certified readers depends on factors like required range, accuracy, and automation needs.

For example, longer-range readers are necessary for locating tubulars in a yard, while short-range readers may be used for specific tasks, like tripping pipes or tracking adjacent pipes on racks.

The wide range of reader shapes and sizes allows for flexible installation in the field without disrupting operations, ensuring safety and data capture efficiency in critical environments.

How does oil and gas asset management software improve operations?

Oil and gas asset management software links each asset to a comprehensive database containing crucial data, such as inspection reports, manufacturer documentation, and operational history. This integration enhances visibility across the office, yard, and rig floor.

In the field, a tool pusher can easily access the asset’s inspection history and measurements via a handheld device, while inspectors and repair shops can track detailed operational data, such as wear metrics and asset location.

The system’s user-friendly interfaces minimize the need for change management, ensuring smooth adoption. Ultimately, these systems provide valuable data for process optimization, risk reduction, and improved operational efficiency.

How does RFID tracking benefit Mining operations?

RFID technology in mining enables efficient tracking of tools, heavy equipment, and spare parts, ensuring real-time visibility, maintenance scheduling, and compliance with safety standards.

It helps mining operators monitor the condition and location of critical assets, from grinding and crushing equipment to underground tools.

Additionally, service providers use RFID to manage rental equipment in the field, tracking usage, maintenance, and movement to optimize asset utilization and reduce operational downtime.

How is RFID used in Construction for asset and tool tracking?

RFID technology enhances construction operations by automating the tracking of tools, rental equipment, and critical infrastructure components like pipes and machinery.

It also supports efficient inventory management, minimizes loss, and boosts operational productivity.

Passive RFID sensing is increasingly used to monitor concrete curing, ensuring optimal timing for infrastructure projects. Additionally, RFID systems for equipment tracking streamline maintenance, improve lifecycle management, and ensure compliance with safety standards.