XSKIN series

Specialty RFID Labeling Optimized for Durable Tracking in Systems and Workflows

The XSKIN series from Xerafy introduces advanced RFID labeling solutions engineered for tracking on non-metal surfaces. These versatile labels and inlays are particularly suited for sectors like healthcare, retail, and logistics, where reliability and durability in tracking systems are essential for efficient inventory and asset management.

XSKIN labels are tailored for applications where traditional metal tags are unsuitable. They offer excellent performance under various environmental conditions, including exposure to high temperatures or gamma irradiation and their flexible design adapts seamlessly to curved surfaces. The range includes specialized labels and inlays designed to endure rigorous industrial processes, ensuring robust performance across multiple use cases.

Designed with industry-leading companies, XSKIN labels are deployed in environments that demand non-intrusive, reliable labeling solutions. These labels comply with strict industry regulations, ensuring they meet high standards of performance and durability necessary for critical tracking operations.

“These innovative labeling solutions help industry players reap the enormous benefits of EPC/RFID and make cost-effective tracking a reality.”

Complementing the specialties featured in the XSKIN series, Xerafy’s Metal Skin® offer durable on-metal labeling solutions, designed for seamless integration into existing systems. Together with the POD TRAK series of durable tags, these products ensure comprehensive tracking capabilities across all surface types and durability requirements, catering to a wide range of industry needs.

Specialty RFID Labels and Inlays That Outperform

The RFID labels and inlays in the XSKIN series offer specialty off-metal labeling solutions across all surface types and durability requirements, catering to a wide range of industry needs

Conversion

Ready for high-volume converting and production

Specialty

Unique specialized features for optimal performance

Off Metal

RF performance optimized for off-metal use cases

XSKIN Baggage 50.8

Accurate RFID for Baggage Tracking

The XSKIN Baggage 50.8 label is designed for precise and reliable baggage tracking. Its omni-directional performance delivers fast, consistent reads at ranges up to 7 meters off metal surfaces. With global RAIN RFID compatibility, it supports seamless deployment and integration across international airport operations.

Featuring up to 240 bits of EPC memory and dedicated user memory, the label provides secure, detailed data encoding for accurate identification and traceability. Its compact 50.8 x 50.8 mm form factor is ideal for baggage labels, while the passive, battery-free design ensures scalable, cost-efficient rollouts. Supplied in roll format for high-volume printing, it is optimized for industrial adhesive application and printer compatibility.

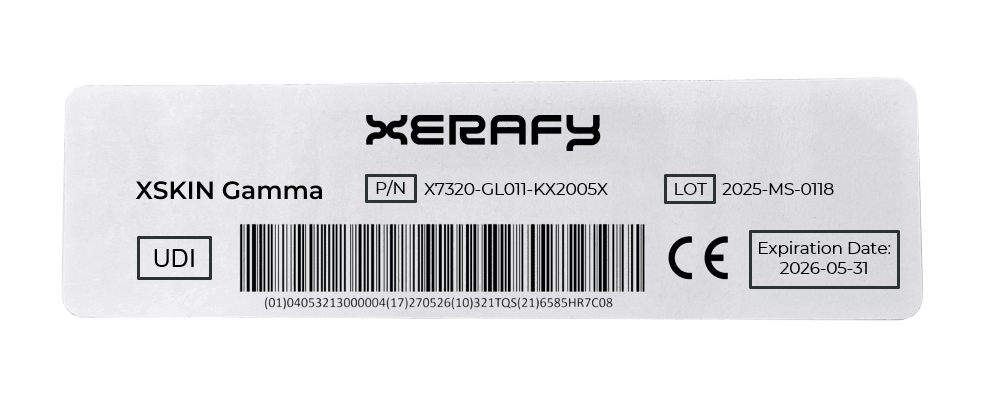

XSKIN Gamma 73x20

Durable RFID for Gamma Sterilization

The XSKIN Gamma 73 x 20 is designed to withstand repeated Gamma and E-beam sterilization cycles, while supporting global RAIN RFID standards for international deployments.

Featuring 128 bits EPC and 1312 bits user memory, it supports secure, detailed data encoding. Its large printable area (73x20mm) ensures easy branding and ID, and it’s cost-effective for large-scale deployments. Available in wet or dry inlay formats, it’s ready for high-volume label conversion.

XSKIN Theta

Precision RFID for Injection Molding

The XSKIN Theta is a specially designed off-metal RFID inlay optimized for integration via injection molding processes.

Operating across global RAIN RFID frequencies, this thin and flexible inlay withstands temperatures up to 230°C. It offers manufacturers and distributors a robust, high-temperature solution for RFID source tagging, streamlining inventory management and production tracking with unparalleled efficiency and reliability.

How to Print, Mark, Encode, and

Custom Design?

All RFID labeling solutions in our XSKIN series can be personalized

to support the deployment of your RFID system

Printing

Compatible with thermal transfer printing: Serial numbers, IDs, Logo, 1D and 2D Barcodes

Marking

Support

durable identification

Encoding

Support unique IDs

and serialization for item-level tracking

Engineering

Support for custom adhesives, sizes, face materials

Case Studies

The Xerafy XSKIN series of off-metal RFID inlays provide flexible RF identification and tracking capabilities to specialized tracking systems:

FAQs RFID Labeling with XSKIN Series

What environmental and durability tests have XSKIN labels undergone?

XSKIN labels are engineered for durability and reliability in harsh environments, including exposure to sterilization processes and industrial processes.

Each label undergoes rigorous testing based on its intended use case. Detailed test data is available in each product’s datasheet. For application-specific recommendations, contact the Xerafy Engineering team.

Are XSKIN labels compatible with standard RFID readers?

Yes. All XSKIN labels are based on passive UHF RAIN RFID technology, compliant with EPCglobal Gen2v2 and ISO 18000-63 standards. They work with a wide range of fixed and handheld RFID readers used in healthcare, logistics, manufacturing, and cleanroom environments.

For optimal performance, reader frequency range and antenna configuration should match the RFID labeling specification.

How is XSKIN Gamma used in healthcare and medical device manufacturing?

XSKIN Gamma enables RFID labeling of assets that undergo gamma irradiation sterilization (typically 25–50 kGy) in compliance with ISO 11137 and FDA standards.

Applications include:

+ Single-use and reusable medical devices

+ Surgical trays and kits

+ Pharmaceutical packaging and supply chain traceability

+ UDI compliance via encoded EPC and user memory

The label maintains integrity through terminal sterilization and supports tracking in high-throughput environments.

Can XSKIN Gamma be used on reusable assets?

Yes. XSKIN Gamma is suitable for reusable medical devices, trays, and PPE that are repeatedly sterilized using gamma irradiation. While the label supports high doses (up to 50 kGy), its memory is encoded once during production or at the point of packaging. This makes it ideal for serialized workflows where data does not change after initial encoding.

What RFID labels are available for other sterilization techniques?

Xerafy offers RFID tagging solutions for various sterilization methods beyond gamma irradiation:

+ Autoclave sterilization – High-temperature, high-pressure cycles: Use MICRO Medical or Autoclave tags

+ Ethylene Oxide (EtO) sterilization – Chemical gas sterilization: Select XSKIN Gamma or Autoclave-ready variants

+ E-beam sterilization – Shorter penetration: Use Gamma-compatible tags

Each label is tested for compatibility with the respective sterilization method. Contact the Xerafy engineering team to select the most suitable option for your packaging and process.

Are XSKIN labels compatible with disinfection, sanitization, or pasteurization processes?

Yes. Depending on the process, Xerafy offers suitable labels:

+ Disinfection and sanitization (UV, chemical wipe-downs): Most XSKIN labels can withstand typical surface treatments

+ Low-temperature pasteurization: XSKIN Gamma is ideal for food items undergoing irradiation-based pasteurization

+ Steam-based cleaning: Use METAL SKIN or XSKIN inlays and labels for environments with high moisture and heat exposure

Label selection depends on exposure duration, temperature, and chemicals used.

How is XSKIN Gamma used in food processing and phytosanitary packaging?

XSKIN Gamma is used to tag food products and packaging exposed to gamma irradiation during pasteurization or phytosanitary processing.

These treatments typically involve doses below 10 kGy and are applied to:

+ Perishable and export food items

+ Reusable transport containers and bins

+ Packaging undergoing microbial reduction

The label ensures reliable tracking while maintaining sterility and compliance with food safety regulations, throughout the supply chain.

Can XSKIN Gamma be used in NDT inspections?

Yes. XSKIN Gamma is suitable for assets that undergo radiographic NDT inspections, including gamma-ray and X-ray exposure. It maintains data integrity and read performance even after repeated exposure.

Typical use cases include aerospace components, industrial parts, and materials inspection samples tracked during radiography.

How is XSKIN Gamma used in electronics manufacturing?

RFID labels resistant to gamma irradiation can be applied in electronics manufacturing processes, especially in cleanroom environments, to track the movement and status of sensitive electronic components.

What types of assets and products can be tagged with the XSKIN Theta?

The XSKIN Theta RFID label is exceptionally versatile, designed to tag a diverse range of assets in various industries. It is particularly useful in environments where traditional labels might fail due to exposure to high temperatures and rigorous processing conditions. Typical applications include tagging automotive components during manufacturing processes, electronic devices that undergo stringent quality control, and other industrial products that require durable and reliable tracking solutions. This adaptability makes Theta an ideal choice for manufacturers seeking efficient asset management.