RFID for Tool Tracking

and MRO Operations

Driving safety, efficiency, and compliance through RFID-powered automation and digitization in high-stakes, precision-driven maintenance operations

Maintaining tools and equipment in high-stakes environments such as aerospace, rail, construction, and manufacturing comes with unique challenges. RFID technology enables real-time tracking, lifecycle monitoring, and proactive maintenance automation to improve efficiency, ensure safety, and maintain regulatory compliance across mission-critical industries.

Xerafy has led the charge in evolving RFID from a foundational inventory management tool to a transformative solution for tool tracking and MRO workflows. Our RFID tagging solutions, co-developed with industry leaders, are engineered to perform under the harshest conditions, addressing key challenges such as tool loss, preventive maintenance, and visibility into tool usage.

From preventing FOD incidents in aerospace to streamlining tool inventory and maintenance in manufacturing, Xerafy’s RFID technology provide a reliable, scalable solution to enhance operational control. Our case studies showcase how industries like aerospace, defense, energy, and construction are leveraging RFID to optimize workflows, reduce downtime, and improve asset accountability. Whether it’s tracking tools, managing supplies, or optimizing maintenance schedules, Xerafy’s RFID technology is redefining operational excellence in precision-driven, high-risk industries.

In high-stakes industries like aerospace, nuclear, and power generation, tool control is critical to ensuring operational safety and compliance. The prevention of Foreign Object Debris (FOD) and Foreign Material Exclusion (FME) incidents is essential to avoid catastrophic consequences and meet regulatory standards like FAA compliance in aerospace.

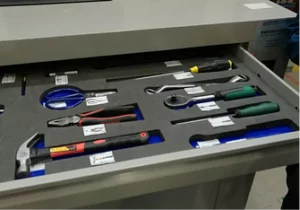

Traditional tool control methods—manual sign-in/sign-out logs, foam organizers, and visual checks—lack accuracy and situational awareness, leading to unaccounted tools, safety risks, and operational downtime. For example, misplaced tools in turbine maintenance or military field kits can compromise mission success and worker safety.

Automated Tool Control (ATC) systems featuring Xerafy RFID transform tool management with smart solutions like tool cribs, cabinets, trolleys, and kiosks. These systems enable real-time tracking of tools, issue alerts for missing items, and integrate with safety protocols. Their small rugged RFID tags ensure reliability across challenging environments, from aircraft MRO operations to military field maintenance.

RFID-enabled tool control ensures safety, efficiency, and compliance in critical environments:

- Enhanced Safety: Eliminate FOD/FME risks through real-time accountability.

- Improved Efficiency: Streamline tool tracking and reduce downtime.

- Compliance Assurance: Meet stringent industry standards, such as FAA guidelines.

- Cost Savings: Prevent tool loss and reduce manual tracking errors.

Tool inventory management is critical for industries like manufacturing, maintenance, construction, and infrastructure. Ensuring tools—whether hand tools, power tools, or calibrated tools—are available and compliant is vital for productivity and operational continuity, particularly in field operations, rentals, and tool kitting workflows.

Manual processes often lead to:

- Misplacement or theft of tools, resulting in high replacement costs.

- Delays due to inefficient check-in/check-out processes or lost tools.

- Non-compliance risks from untracked calibration schedules.

- Inefficiencies in assembling and deploying toolkits (kitting), especially in manufacturing and field environments.

Xerafy’s RFID tool tagging solutions provide real-time tool tracking, streamlining inventory management. RFID tags facilitate accurate check-in/check-out workflows, enable kitting optimization for manufacturing and field operations, and ensure calibration compliance. Small rugged tags withstand harsh industrial environments, ensuring reliability.

RFID tool inventory management transforms tool utilization, ensuring tools are where they’re needed, when they’re needed:

- Improved Availability: Tools are easy to locate, reducing downtime.

- Enhanced Compliance: Calibration tracking prevents errors and ensures quality standards.

- Cost Efficiency: Lower tool replacement costs and improved productivity.

- Operational Efficiency: Minimized manual processes and delays.

Specialized tooling, such as injection molds, foundry molds, and dies, is critical to manufacturing and automotive industries. Effective management of these assets ensures efficient production processes and protects intellectual property.

Managing tooling across multiple sites involves:

- Inefficient usage and increased downtime due to manual tracking.

- Lack of traceability, leading to production delays.

- Risk of IP theft or loss in supplier networks.

Xerafy’s RFID tagging solutions enable real-time tracking of tooling assets, optimizing usage, scheduling maintenance, and ensuring traceability. RFID tags can withstand harsh manufacturing environments and integrate seamlessly with production management systems.

RFID transforms tooling management, supporting precise and efficient production workflows.

- Enhanced Efficiency: Reduced downtime and optimized tool usage.

- Improved Traceability: Ensure molds and dies are where they’re needed, when they’re needed.

- IP Protection: Track tooling across the supply chain to prevent loss or theft.

- Cost Savings: Minimize production disruptions and extend tool lifespan.

MRO parts are essential for maintaining operational efficiency across industries. Effective management ensures just-in-time (JIT) inventory, cost control, and authenticity of critical parts, directly impacting productivity and operational reliability.

Challenges:

- Managing JIT inventory to avoid shortages or excess stock.

- Ballooning costs due to misplaced or untracked parts.

- Ensuring part authenticity to prevent operational failures and compliance issues.

Xerafy’s RFID tagging solutions provide seamless tracking for MRO parts, integrating with tool inventory systems for unified management. Rugged RFID tags ensure traceability, prevent loss, and support JIT replenishment workflows.

RFID optimizes MRO parts management, improving reliability and reducing operational risks:

- Efficiency: Reduce downtime with accurate part availability.

- Cost Control: Minimize excess inventory and replacement costs.

- Traceability: Ensure authenticity and compliance with regulatory standards.

- Integration: Unified management of tools and parts for streamlined operations.

Managing MRO inventory—including supplies, consumables, and materials—is essential for maintaining operational efficiency. Accurate tracking of expiration dates, traceability, and timely replenishment ensures safety, compliance, and cost control across industries.

Challenges:

- Ensuring timely replenishment to avoid downtime or shortages.

- Managing expiration tracking for regulated industries like aerospace and food manufacturing.

- Lack of traceability for critical supplies, leading to inefficiencies and non-compliance.

Xerafy’s RFID tagging solutions automate inventory management, enabling real-time tracking of consumables and materials. Integration with vending machines ensures automated replenishment, while RFID tags ensure compliance with expiration and traceability standards, even in Foreign Material Exclusion (FME) environments.

RFID transforms MRO inventory management into a streamlined, reliable process for maintaining operational excellence:

- Improved Efficiency: Automated replenishment reduces downtime and manual efforts.

- Compliance Assurance: Ensure regulatory adherence with traceability and expiration tracking.

- Cost Control: Minimize waste by optimizing inventory usage.

- Enhanced Safety: Support FME practices in critical environments.

Case Studies RFID Tool Tracking and MRO

From aerospace tools to automotive tooling and construction equipment, see how Xerafy’s field-tested RFID technology is transforming tool tracking and MRO operations worldwide

Benefits of RFID for Tool Tracking and MRO

FOD Prevention and Safety

Prevent FOD/FME risks with real-time tool tracking, ensuring accountability and compliance in mission-critical environments

Enhanced Productivity

Streamline tool and inventory workflows by identifying inefficiencies and improving access to tools and MRO parts

Complete Visibility

Gain real-time insights into tool movements, usage history, and MRO inventory status, enabling proactive decision-making

Maintenance Optimization

Automate tracking of tool condition, calibration schedules, and lifecycle status to minimize downtime and enhance reliability

Actionable Analytics

Leverage data on tool and inventory usage to optimize resources, identify shortages, and ensure timely replenishment

FAQs RFID Tool Tracking and MRO

What are the challenges of MRO tool control?

Managing MRO tool control involves several challenges that impact safety, efficiency, and costs:

Cost

Tool inventory shrinkage and service costs of manual management (audit time, downtime)

Visibility

Limited real-time data on tool location, availability, or status

productivity

Time-consuming manual check-in/check-out processes and delays in locating tools

Safety

Increased FOD/FME risks from unaccounted or misplaced tools

Program Impact

Missed deadlines, AOG risk, delivery delays

Compliance

Difficulty ensuring calibration and maintenance schedules are followed

RFID automates tool tracking, improves accountability, and enhances operational efficiency, directly addressing these challenges.

How does RFID compare to other technologies for tool tracking?

UHF RFID is a leading technology for automating tool tracking due to its ability to scan multiple items simultaneously without line-of-sight, unlike barcodes or QR codes that require manual, direct scans.

It outperforms NFC by offering significantly longer read ranges and BLE by eliminating the need for battery-powered tags, reducing maintenance costs.

While GPS excels at tracking large equipment over large distances, UHF RFID is optimized for precise, localized tracking in environments like tool cribs or maintenance areas, making it ideal for industries like aerospace, manufacturing, and construction.

How do you set up an RFID tool tracking system?

Setting up an RFID tool tracking system involves combining hardware, software, and workflows tailored to your operations, while ensuring real-time visibility and seamless integration with existing processes.

- RFID Readers: Deploy fixed readers for continuous or event-triggered inventory (e.g., door openings) and handheld readers for flexible inspections and tool searches. Integrate these with fixed or mobile storage like tool cribs, cabinets, or vans.

- RFID Tags: Use rugged, on-metal, or embedded tags suited for different tool sizes and materials, designed to withstand shocks, heat, and chemicals.

- Software & Integration: Connect RFID data with ERP, MES, or calibration systems for centralized reporting, compliance tracking, and lifecycle management. Support both online and offline modes to maintain security and continuity in sensitive environments.

- Access Control: Protect specialty tools with login methods such as badges, biometrics, or PINs, ensuring only authorized users can check out equipment.

- Reporting & Analytics: Automate tool usage logs, calibration reminders, and audit reports, giving managers actionable insights to improve efficiency and compliance.

A well-designed RFID system not only tracks tools but also integrates into your broader MRO ecosystem, improving accountability, compliance, and operational efficiency.

How does RFID integrate with existing MRO systems?

RFID tool tracking systems are designed to work alongside your existing IT infrastructure. Integration options include:

> Interfaces and Connectivity: Standard data interfaces such as Ethernet (RJ45), USB, and serial ports ensure compatibility with ERP, MES, or calibration systems.

> Offline Mode: Systems can operate in standalone mode when network connectivity is restricted, preserving data integrity and security.

> Data Exchange: RFID software supports import/export in formats like Excel and enables automated reporting, inventory queries, and tool usage logs.

This ensures RFID can be deployed without disrupting established workflows, while enhancing traceability and compliance.

Some legacy ERP systems are not RFID-ready, for example platforms like TRAX may face limitations, but migration to next-generation systems such as eMRO introduces native RFID capabilities. This trend reflects a broader industry shift towards ERP/MRO systems that support RFID for tool control.

What are best practices for implementing RFID tool tracking?

Successfully implementing RFID tool tracking involves these best practices:

DEFINE ROI GOALS

Identify specific problems (e.g., tool loss or inefficiencies) and measure expected outcomes like cost savings or increased productivity

Evaluate Existing Systems

Review current processes, such as manual logs or barcodes, and identify areas for improvement

Tool Inventory Assessment

Catalog tools, storage units, and equipment to determine tagging needs

Strategic Deployment

Start with proof of concept and scale gradually, ensuring redundancy and quality

Change Management

Formal training centers and ongoing support

Integrate Connected Tools

Leverage tools with native RFID features for easier adoption or future-proof procurement

Resources like case studies and engineering support are essential for tailoring the system to your organization’s needs.

What safeguards ensure reliability during downtime or power loss?

RFID-enabled systems incorporate multiple safeguards to ensure tools remain accessible and secure in all situations:

> Battery Backup: Tool cabinets or carts include integrated power storage for continuous operation during outages.

> Fail-Safe Access: In emergencies, tools can still be accessed using mechanical overrides or backup keys.

> Service Guarantees: Vendors typically provide SLAs with rapid response times and spare parts availability to minimize downtime.

These features ensure uninterrupted tool tracking and secure access, even under adverse conditions.

Which RFID tags are best suited for different types of tools?

Xerafy offers a range of rugged RFID tags tailored for tool tracking in demanding environments. Engineers can select tags based on tool size, material, and operational conditions:

> Specifications: Designed for durability (e.g., IP68), metal interference resistance, and optimal read ranges.

> Tag Selection: Options for on-metal and embedded tagging, suited for tools exposed to harsh conditions like high temperatures, abrasion, and chemicals.

> Tagging Methods: Attach tags using epoxy, heat-shrink tubing, or direct embedding.

Support is available from the Xerafy engineering team for customized solutions.

What if certain tools cannot be tagged with RFID?

Not every tool or instrument can accommodate an RFID tag due to size, shape, or material constraints. In such cases:

> Alternative Identification: Manual binding, barcoding, or other recognition methods can be applied.

> Hybrid Tracking: RFID-enabled carts or cabinets can combine RFID with non-RFID identification to ensure complete coverage.

> Future-Proofing: Many tool manufacturers now offer “Connected Tools” with native RFID features, reducing the need for retrofits.

This hybrid approach ensures that every tool — even untaggable ones — remains accounted for within the tracking system.

Connected Tools are professional tools with native RFID features integrated into their design by manufacturers, enabling tracking, identification, location, and usage data capture.

Unlike retrofitted tools, these tools are equipped with embedded RFID chips during manufacturing, offering enhanced functionality for tool management and FOD prevention.

Xerafy collaborates with leading manufacturers like Cribmaster, FAcom, Kyoto Tools, and SnapOn to pioneer these innovations, meeting industry demands for smarter, more efficient tool management solutions.

How can RFID track sockets, small tools, and other difficult-to-tag items?

With sockets and ratchets accounting for up to 30% of a typical MRO tool inventory, delivering a near 100% tool tracking coverage is critical in environments prone to FME and FOD incidents.

But given their small sizes, traditional tool tagging solutions are limited given that there really is no good place to mount an RFID tag that won’t interfere with daily operation:

> Size Constraints: Small tools are harder to tag without compromising usability.

> Durability: Tools face wear and tear in demanding environments.

Xerafy’s miniature and rugged RFID tags are designed to meet these challenges, ensuring reliable tracking even for the smallest tools in harsh conditions. The RFID tags can be embedded or attached to sockets and small tools, enabling real-time inventory tracking to prevent loss or misplacement.

How does RFID ensure compliance with calibration and maintenance requirements?

RFID tool tracking goes beyond location tracking by monitoring tool lifecycle and compliance needs:

> Calibration Alerts: Tools can be flagged for scheduled calibration and blocked from use if overdue.

> Usage Logs: Borrow/return data helps predict when tools need inspection or replacement.

> Automated Reporting: Compliance reports can be generated for audits, reducing manual record-keeping errors.

By digitizing calibration and maintenance workflows, RFID helps organizations maintain compliance with industry and regulatory standards.

How does RFID help with predictive and preventive maintenance?

RFID enables predictive and preventive maintenance by tracking tool usage, lifecycle, and calibration schedules. Moreover, passive RFID sensing can monitor environmental factors like temperature or pressure, providing real-time insights into tool and equipment conditions.

This data allows for early detection of wear or anomalies, triggering maintenance alerts before failures occur. Integration with maintenance software further enhances planning and minimizes unplanned downtime, ensuring operational efficiency.