RFID Tags

For

Tools

Pallets

Assets

Parts

Drill Pipes

Totes

IT Assets

Inventory

Surgical Trays

RFID Tags for Asset Tracking, Returnables, and Inventory: UHF, Passive, Metal, Rugged, Printable, Encoded, Small, High Temperatures, Embedded, Memory, ATEX.

Tagging solutions that deliver performance, reliability, and consistency at the service of specialized asset identification and tracking systems:

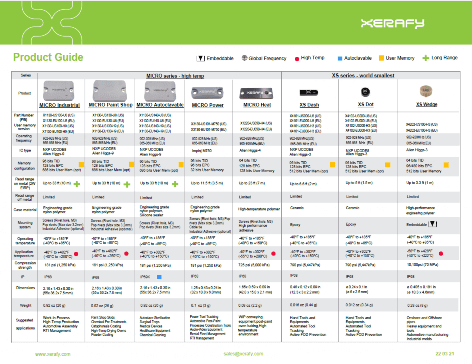

RUGGED

Benchmark-topping rugged RFID tags for critical assets

TRAK

Durable RFID tags for returnable assets and inventory

SKIN

Smart RFID labels for complex supply chains

IOT

Devices for asset tracking and monitoring

Companies all over the world trust Xerafy for their critical tracking systems:

6 Steps To Successful RFID Tagging

How do you select RFID tags for asset tracking? Xerafy’s 6-Step ABCDEF approach helps frame your essential performance requirements.

What assets does the RFID system track?

Start with the type of assets to be tracked and the materials they are made of: Metal tagging is the most common use case in industrial systems alongside plastics. Other materials include wood, glass, cardboard, and so on.

RFID tags are typically applied to the surface of the asset to be tracked. The composition of the substrate and the nature of the content of the asset can have an impact on the overall performance of the tracking system, such as read range, accuracy, and durability.

Industrial RFID tags are specifically designed as mount on metal RFID tags, with a spacer to ensure optimal RF performance. Xerafy took it a step further by developing a metal tagging technology that leverages the presence of metal in the asset to improve its RF performance in terms of accuracy and read range. Xerafy developed a range of rugged RFID tags that are optimized for high performance on metal surfaces.

Which bonding method is the most appropriate for the system?

A number of parameters must be considered when defining an optimal tagging method in terms of operational performance and ROI, including:

- What is the asset's lifespan?

- What is the expected rate of tag attrition?

- Is it necessary for RFID tags to be reusable and replaceable?

- Is there any legacy inventory that must be retrofitted with RFID tags?

- How scalable and fast must the tagging method be?

Each industry has its preferences for field-validated tagging methods such as rivets, screws, welding, glues, adhesives, magnets, velcro, cables, and zip ties. Xerafy's expertise in specialized tracking systems has resulted in the development of RFID metal tagging solutions that operates inside metal, also known as embeddable RFID, in which the tag is screwed into a cavity or sealed.

How much customization is required for the RFID system to be deployed?

Asset tracking applications benefit from a wide range of standardized tags, readers, antennas, and software that are readily available off the shelf. Personalization on-site or by the supplier can facilitate field deployment: Printing of readable identification, RFID encoding of asset data, personalized laser engraving, RFID reader tuning, and so on.

RFID tags can be personalized and customized for deployment in the field, including printing, encoding, laser marking, etc.

RFID has proven to be a compelling solution to barcode identification's limitations in terms of line of sight, bulk scanning, and automation. Tags support hybrid RFID and optical information in the form of human-readable data or Barcodes / QR codes.

Xerafy UHF labels in particular can be supplied blank, to be then printed and encoded on-site with any of the leading RFID printers such as SATO, Zebra, Toshiba, Printronix, and Postek. They can also be personalized with the support of the Xerafy service bureau.

How is data stored in the RFID system?

RFID tracking systems reliably identify assets with the information stored in the RFID asset tags' memory. They are increasingly relying on RFID tags, which only store an asset identification number and store information in the cloud. This is due, in part, to applications that operate at faster speeds than RFID chips can read and write.

The following RFID chips memory can be used for identification:

- TID memory - Also known as Tag ID, this is a serial number that is unique to the chip and cannot be changed.

- EPC memory - Also known as Electronic Product Code memory, it is similar to an electronic barcode and can be reprogrammed, password-protected, and permanently locked.

- Extended user memory - Some chips provide extended user memory, which is typically used when EPC memory is insufficient.

Higher memory requirements are found in application environments that require off-line access to complete records, secure encryption, or come with field-based cloud coverage limitations. Xerafy maintains a selection of RFID chips with extended user memory from market leaders NXP, Impinj, and Alien Technologies

What are the RFID system's environmental conditions?

Rugged RFID tags come in a variety of tough packagings that are designed to provide levels of survivability and durability appropriate to the system's requirements. It is therefore critical to specify the environmental conditions under which the RFID solution operates, for example:

- Extreme heat?

- Temperature fluctuations?

- Vibrations and shocks?

- Moisture or immersion?

- What about caustic or acidic fluids?

- Operations indoors or outdoors?

Some application environments, such as an automotive paint shop, are more complex than others. Xerafy has used its application expertise to create several sector-specific tagging solutions that have brought RFID tracking technology innovations to market.

Where to place the asset's tag for optimal system performance?

RFID tracking solutions deal with various physical constraints that must be considered when choosing an RFID tag: Size and shape of the objects, space on the asset's surface available for tagging, curvature of the surface, optimal placement in relation to the workflow, and so on.

While RFID tags are available in a variety of sizes and shapes, RF performance tends to evolve in conjunction with the overall tag size. With a lineup of tags achieving outstanding performance in some of the world's most compact and rugged form factors, Xerafy innovation in the field managed to break through the RFID size/performance ceiling.

What are UHF RFID tags?

UHF RFID (Ultra High Frequency Radio-Frequency Identification) tags are a type of RFID technology that operates at RFID frequencies between 300 MHz and 3 GHz.

The tags consist of a small antenna and a microchip that stores data about the object being tagged. When the tag is within range of an RFID reader, the reader sends a signal to the tag, which responds with its unique identification number and any other data programmed into the chip. This information can then be used to track and manage the tagged object.

Unlike barcodes, UHF RFID allows for reading and writing data in bulk, in seconds, from a distance, and out of sight, thus enabling automated asset tracking.

What protocols are supported by the Xerafy RFID Tags?

The Xerafy RFID tags use the RFID protocol EPC Class1 Gen2, which is designed to enable efficient communication between the tag and the RFID reader. The RFID protocol ensures reliable data transmission and facilitates inventory management and tracking processes.

How do metal-mount RFID tags differ from regular labels?

Metal RFID tags are different from regular RFID tags as they are specifically designed to perform optimally when attached to metal objects. This means that they are ideal for tracking computers and IT assets, tools, machinery, returnable containers, medical devices, and other metal items.

Metal presents challenges for regular labels and will impact their performance:

- Metal surfaces reflect, scatter, or absorb RF signals, which can interfere with the performance of the RFID system.

- Metal objects can also detune the RFID antenna, which can cause the system to fail.

Metal RFID tags come with unique antenna designs and materials and a special shielding layer that helps to minimize interference from the metal surface and prevent the detuning of the tag’s antenna. These tags typically have a thicker substrate than regular RFID tags, which helps to protect the tag from damage.

Additionally, metal-mount RFID tags are often encapsulated, providing extra protection and durability compared to regular labels.

Can a RFID tag work in metal?

Yes, an embeddable RFID tag is a metal RFID tag designed to be embedded inside metal objects such as tools or equipment.

Embeddable tags have a special design that allows them to work effectively despite being surrounded by metal. These tags are typically smaller and thinner than on-metal tags, which makes them easier to embed in metal objects.

It is essential to select tags that are specifically designed for use in metal and to test their performance in the specific application environment before deploying them for asset tracking.

What are the maximum temperatures for RFID tags?

Industrial RFID tags are specifically engineered to operate within a wide temperature range to withstand harsh environments, with maximum temperatures depending on the specific type of the tag.

Xerafy’s industrial RFID tags can typically reach 70-85C, with specialty products going higher:

250C – ROSWELL series for Oil and Gas industry, MICRO Industrial and Paint Shop for Manufacturing

230C – XSKIN Theta for injection molding

220C – XS Wedge

200C – MICRO Heat

It’s also worth noting that while some RFID tags can withstand high temperatures, they may not function optimally at these extreme temperatures.

It is recommended to select RFID tags specifically designed and tested for the temperature range of the intended application to ensure reliable and accurate performance.

What's the difference between operating and survival temperatures?

Operating temperatures is the range within which a tag can be read.

Survival temperature is the maximum heat the tag can endure.

Operating temperature:

This is the range of temperatures within which the RFID tag can function properly.

In simpler terms, it’s the temperature range where the tag can read and write data reliably.

Operating temperatures typically fall within a specific range, such as -40°C to +85°C for certain passive UHF tags.

Exceeding the operating temperature range can lead to malfunctions, data errors, or even permanent damage to the tag’s internal components.

Survival temperature:

This refers to the maximum temperature that the RFID tag can withstand without sustaining physical damage.

Think of it as the tag’s tolerance for short-term exposure to extreme heat.

Survival temperatures are generally higher than operating temperatures.

What is Read Write RFID?

Read Write RFID is a type of RFID technology that allows data to be both read from and written to an RFID tag. Most RFID systems are designed for read-only operations, where data is simply read from the tag and transmitted to the reader. However, with read-write RFID tags, the RFID reader can also write data to the tag, allowing for two-way communication between the tag and reader.

Read-write RFID tags have a read-write memory chip that can store and transmit data back to the reader. These tags are typically used in more complex applications that require a higher level of data management and control. It is commonly used in applications such as inventory management, asset tracking, and supply chain management, where real-time data updates and bi-directional communication between the tag and reader are critical.

To read write RFID, the information is written in the chip using an RFID reader or an industrial RFID printer. RFID tags programming can be done in the field, or can be taken care of by the Service Bureau of the manufacturer or distributor.

Do RFID tags come with memory?

Yes, some RFID tags do come with memory, such as the Xerafy MICRO RFID tags.

The amount of memory available in an RFID tag can vary depending on the tag’s type, frequency, and size. Some RFID tags have only a few bytes of memory, while others have several kilobytes.

The memory in RFID tags can be used to store information such as product codes, serial numbers, customer information, and manufacturing data. This information can be read by RFID readers, allowing businesses to track and manage their inventory, monitor supply chains, and improve their operations.

Passive RFID Tags vs Active?

Passive RFID tags harvest the energy transmitted from an RFID reader. As such, they can operate for many years without any maintenance or battery power, with rugged tags’ life expectancy frequently exceeding that of the asset they are tracking.

Active RFID tags, on the other hand, are powered by a battery, allowing for continuous wireless operations, and communications over longer distances.

Passive and active RFID have long coexisted in industrial applications. Today, active RFID is used mostly in RTLS (Real-Time Locating) systems that are less sensitive to their higher acquisition and maintenance costs.

Can industrial passive UHF RFID tags be customized?

Yes, industrial passive UHF RFID tags can be customized to meet the specific requirements of an application.

Typical customizations for industrial asset tracking systems include:

Printing or labeling: Information such as a logo, serial number, or other identifying information can be printed or labeled on the tag.

Encoding: The data stored on the tag can be customized to include specific information, such as a unique identifier, a product code, or other information relevant to the application.

What is the cost of RFID tags?

RFID tags are available at very different price points:

- Active or Passive – with or without battery

- Form factors – inlays vs hard tags

- Durability – disposable vs reusable

Asset tracking systems rely on durable passive RFID tags. These are available with low deployment costs owing to the early efforts of the RAIN RFID consortium to develop global UHF standards around US, EU/EU2, and Global frequencies.

Specialized tags such as metal RFID tags require special design considerations and materials to ensure that they can function effectively in the presence of metal. This makes them more expensive and harder to manufacture than regular RFID tags. However, their ability to work in challenging environments makes them essential for applications such as asset tracking in industrial settings or inventory management in warehouses.

Get In Touch

If you have any questions or need help, feel free to contact with our team.